- 2020-07-15

- share:

We understand that our customers may have their misgivings regarding the newest COB Flexible Strip relative to the normal strip, no worries, we enhance stability, flexibility even heat dissipation by six months testing over and over, it finally proved every procedure are working very well, we have to say that this is a new trend and it is a mature technology at our company. and they are getting better effects and feedback in the market.

Ask: What is COB?

Answer: In the LED world, COB is the abbreviation for Chip on Board, which basically means to package the LED die directly on the circuit board (PCB). The ‘Chip on Board’ LED used on flexible strip lights is also sometimes called a flip-chip. Flip chip LEDs are basically a bare-bones approach to LED structure. Take a look at the normal 5050 SMD (surface mount device) LED, it has a bulkier plastic reflector that encapsulates the LED diode itself and then covers that with a phosphor coating.

The ‘flip chips’ that makeup COB LED strips cut everything from their design except an LED chip, the yellow phosphor covering, and connection pads. This condensed design leads to a significant reduction in size, allowing them to be packed closer together and further miniaturize LED-based lighting

Ask: What is COB technology?

Answer: The new COB (Chip on board) LED lighting technology consists of many small chips integrated into one large single chip, It means that directly package the chip on the circuit board. It is a kind of LED integrated package technology. which differs from the traditional LED (SMD Chips) because instead of individual chips soldered to a circuit board and then mounted to a heat sink; the Wafers are cut into some hundred small chips. These tiny small and hardly visible pieces of semiconductor crystal are bonded directly to the aluminum (with a special bonding procedure) allowing solderless fabrication and maximum heat dissipation.

However, an excellent businessman is good at having an insight into new chance & new market, we hope all of our customers can win it better and better with this new wind direction.

FINELED would like to illustrate several points of advantage for your reference, also you can see a video how do we produce COB flexible strip at http://fine-led.com/index.php?s=/sys/list/31.html.

If you need some samples for presentation to your customers or project investors, you may let us know at any time at admin@fine-led.com.

Ask: How are COB LED Flex Strips Made?

Answer: Chip-on-Board or "COB" refers to the mounting of a bare LED chip in direct contact with a substrate (such as silicon carbide or sapphire) to produce LED arrays. ... For example, a 500 lumen COB LED array can be many times smaller and consume substantially less energy than a 500 lumen SMD or DIP LED Array.

Ask: Advantages of COB LED Flex Strips?

Answer:

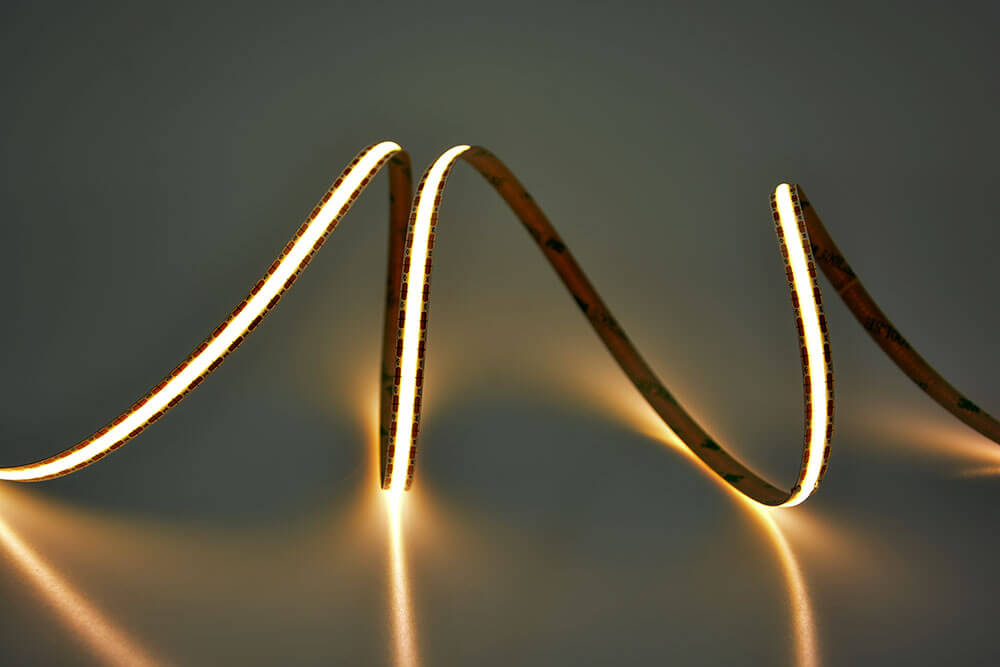

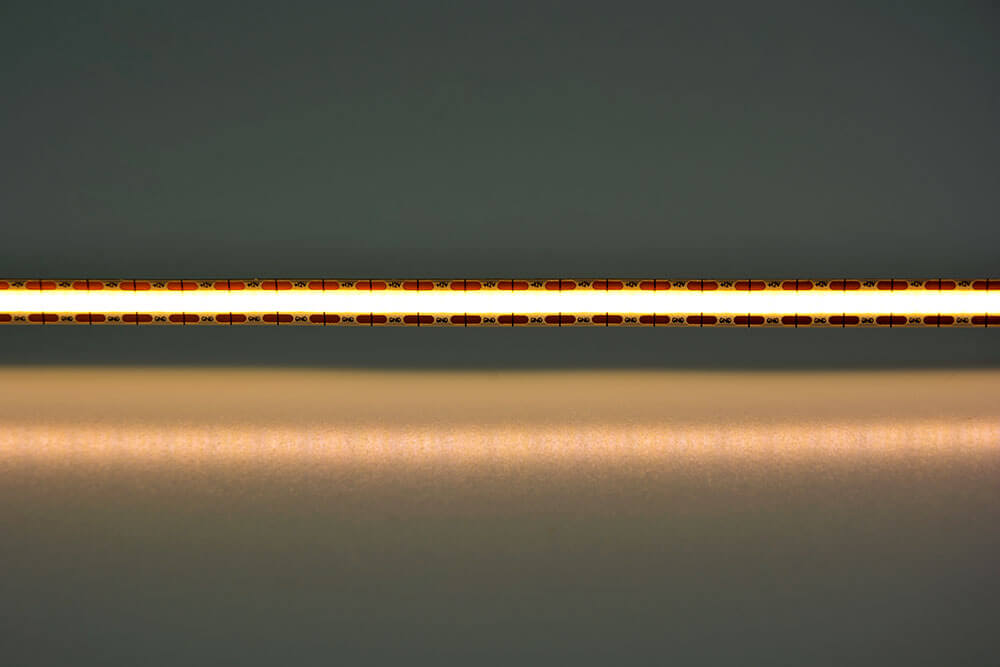

1) The hidden resistor and slim COB LED, good look and luxury appearance The uniform light has no dark spots and is much more attractive to the human eye, giving off a steady light even in the tightest of places. In fact, the only real way to see dot light is to look at the back of the strip where it is easier to see the individually placed flip-chip LEDs. COB LED looks like a linear lighting straight effect and only real way to see no dot light, no light shadow.

2) Dot light free

One of the biggest complaints about your traditional LED flex strip is the dot light throughout the strip. A dot light is the term for the brighter areas through a fixture or strip where you can clearly see where the light is coming from. Light is much more inviting and attractive when it looks like a smooth source of light, not a spotty mess,With 5050 SMD Flex Strips the larger sized diodes are packed close enough so that at a distance the light is spread out and consistent on the surface being illuminated, but if the lights are too close to the surface or the strips themselves are visible, the dot light/shadow are an eyesore that cannot be ignored by the human eye

3) The reasonable working temperature according to the safety standard

They are also much better at distributing heat as they are mounted directly to the flexible PCB board. This helps them spread their heat down into the PCB rather than keeping it all locked right in the light source itself. This reduction of thermal resistance within the high-density circuit greatly improves the lifetime of the LEDs

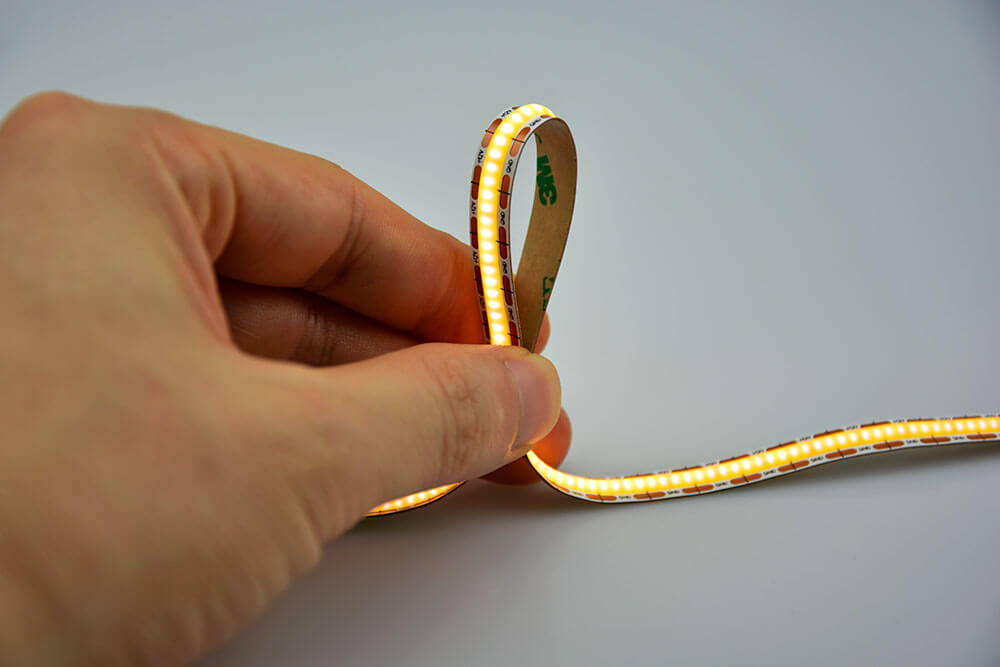

4) The higher flexibility and tenacity, can be folded in 180 degrees without damaging the light strip

The flexibility of these strips is much better than other flexible strips because of the smaller diode size and even distribution of weight. The diodes are so small and tightly spaced that any point of the strip is the same as the other. The uniformity makes it easy to set up strips without having to plan around a 5050 SMD LED sticking out where you don’t need it. This added flexibility will make them easier to fit into tight areas and turn around corners in your application.

5) Fast connector was developed for plug and play

Compatible plug and play connector is a great help to connect with each other after cutting in different and apply in installation location better,

also it can be placed into aluminum profile with COB LED strip together, only confirm what is the width from aluminum profile to fit for.